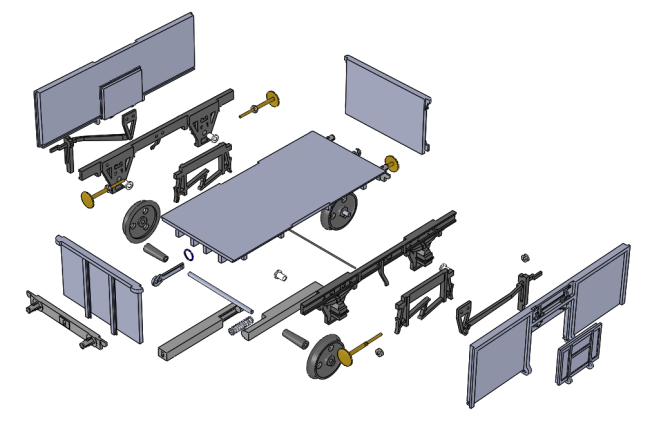

Printable parts inspired by the Airfix/Dapol Kit Re-loaded as the folder originally created in May 2020 was deleted.

Models

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

3D Model

ZIP Archives

Archive

File

Reviews/Comments (subject to moderation)

Comments on 16T Mineral

A very easy and pleasant wagon to build.

No axle length or bearing material is specified for this wagon, and so I made a guess:

I printed the brake assemblies on the FDM printer and so they had a rough inside face - if you are doing the same thing then I would suggest you file back the inside faces of the brake shoes to a smooth surface to ensure they clear the wheels and flanges and reduce drag if any contact is made with lateral movement.

I used 1mm round styrene as a hinge rod for the side doors which must be bowed slightly out of true to pass through the chassis and door brackets. I don't know if this offset was deliberate but it does mean that the wagon doors stay closed.

My goal is to print a rake of 7-9 of these wagons, ideally with only two or three trips to the printer, but I am having trouble with adhesion when the whole bed is occupied and ironing is turned on. When I get a new supply of spray putty I'll see what the un-ironed version looks like and make a call.