Pug Saddle Tank -Revision 2 – Optional changes Aug 2023

This update provides:

1. Revised frames and frame stretchers to allow access for a ball driver/screw driver to the frame side screws with clearance from the wheels. This aids assembly.

2. A revised footplate moves the battery holder forward to give clearance for a firebox LED if desired. Also this footplate accommodates a Hornby HM7000-21TXS Bluetooth DCC decoder and connection adaptor board in place of the previously fitted 'Locoremote' controller.

3. An alternative front buffer beam uses lamp bracket holes in place of integral post which were prone to damage.

4. Any earlier alternative part files are removed to avoid confusion when building.

Pug Saddle Tank -Revision 1 – Optional changes May 2023

1. Motion links / rods

The first release of model files for the Pug paid little attention to the rods and motion other than emulating the plastic kit approach. When reaching the assembly stage of my first prints it was clear that better ‘engineering’ is required to provide a durable motion.

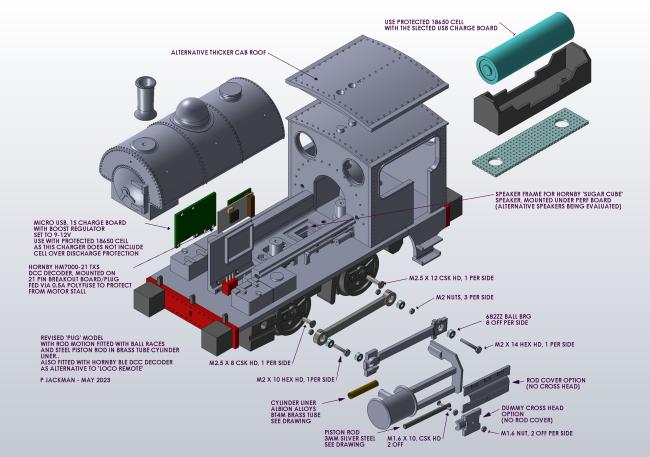

The revised files include rods with recesses to accommodate miniature ball races, 682ZZ. The bores of the bearings at the wheel crank positions sit on M2 screws. The bearings at the cross heads, on M1.6 csk screws. The con rods are now offset outwards at the piston end to allow proper alignment of the motion. Hex nuts are used as spacers and locking elements to ensure this alignment.

Locations of parts are shown in an isometric exploded assembly view now uploaded.

The cylinder liners are 4mm x 3.1mm brass tube. The piston rod is machined from 3mm silver steel. Stainless steel was considered but they are tapped M1.6 and to avoid broken taps I used silver steel.

2. Firebox door

An alternative firebox / cab front is now provided with the firebox door open to allow a flickering red LED mounted at the rear of the battery to provide a flame illumination effect in the cab.

3. Remote Control & Sound

My original Pug trial model used a ‘Locoremote’ module to control the motor.

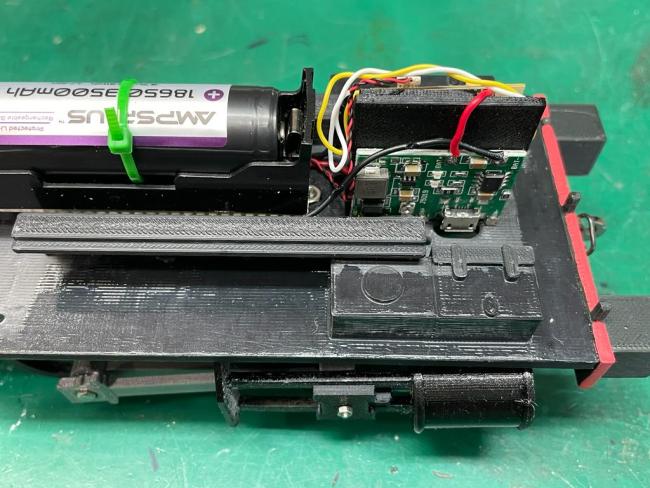

Power was via a 3v-5v boost regulator fed from a USB charge board’s ‘load’ output. The charge board protected the single 18650 Li-io un-protected cell during charge and discharge.

The revised Pug uses a recently released Hornby HM7000-21TXS DCC decoder to power the motor and provide DCC sound and possibly lights. This is feasible with a battery powered loco because the decoder communicates by Bluetooth BLE. To a Hornby App on an Iphone. (Android is not yet supported). The first installation used the Hornby supplied ‘sugar cube’ speaker mounted in a recess under the loco battery. This gave reasonable sound but I managed to damage the speaker by setting the volume too high. Hornby do warn about this. Experiments are now under way with alternative speakers including mobile phone speakers.

Using this decoder requires some changes to the power supply.

3.1 An alternative boost regulator is needed. I chose one incorporating a USB cell charger and with adjustable output voltage. I am currently using 9v to minimise current. The DCC decoder seems to work down to 6v but is spec’d at nominally 16v.

3.2 The decoder output is rated at 1A max. To protect it from excess current, e.g. motor stall etc. I have a 0.5A self resetting polyfuse between the boost regulator output and the decoder. On bench test the 0.5 A polyfuse opened at around 0.8A and reset quickly on removing power. I plan to experiment with external motor drivers behind the decoder to see if larger traction motors can be controlled by the Hornby decoder.

3.3 The adjustable boost regulator/charger can only protect the cell during charging it does not provide cell overload, short or excessive drain protection. For this reason I have now fitted a protected 18650 cell.

If required, more updates will follow as experience with the decoder and alternative loudspeakers is gained is gained.

PRJ.

Original Pug Release below (Feb 2023) ------------------------------------------------

This model was generated at a scale of 10mm/ft. It is inspired by a an 00 scale Airfix kit donated by Keith Bucklitch. Additional design sources were Wickipedia and the book L&Y Railway locomotives by Barry C. Lane (ISBN 978 1 8998 16 7 0)

I have built one trial model. All parts were printed in black HIPS for ease of sanding and solvent weld assembly where required although no post treatment has been done. The model is designed to be assembled by machine screws in captive nuts and/or solvent weld. Various combinations of parts are provided in the print files for flexibility in print methods.

The model uses a low cost motor / right angle dual drive plastic gearbox. These are commonly yellow and available from Aliexpress or Amazon. The motor is rated 3v-6v. Mountings are included for a single 18650 Li-io cell in a commercial cell holder. A small stripboard under the cell holder mounts a 3v-5v step up regulator. A USB charger /cell protect board is included. The single cell voltage is stepped up to 5v to feed a 'Locoremote' controller and hence the motor. The footplate accommodates a small SPCO toggle switch used as the power on/off.

The model design has been waiting since late 2021 to be 'completed'. However as attention has been diverted elsewhere I have up-loaded it now (Feb 2023) at 'Beta' status. Please feel free to print and feed back any assembly or dimensional issues you may find. I will respond to modification requests if I can confirm their need.

Peter Jackman

Reviews/Comments (subject to moderation)